We can help your old favorites get a whole new lease on life.

Media Blasting

MEDIA BLASTING

Media blasting is a great way to strip old rust, oxidation, paint and dirt off any surface in no time at all. Media blasting can prepare your patio furniture, lawn furniture, rims, wheels, automotive parts, motorcycle parts, and almost anything else you can think of that will allow powder coating to adhere better. Media blasting is the latest, greenest technology to safely strip paint and/or clean nearly any surface. The equipment uses compressed air to deliver a cleaning media onto the surface to be cleaned. Similar in concept to sand blasting, media blasting is much kinder and gentler to the underlying surface and the environment.

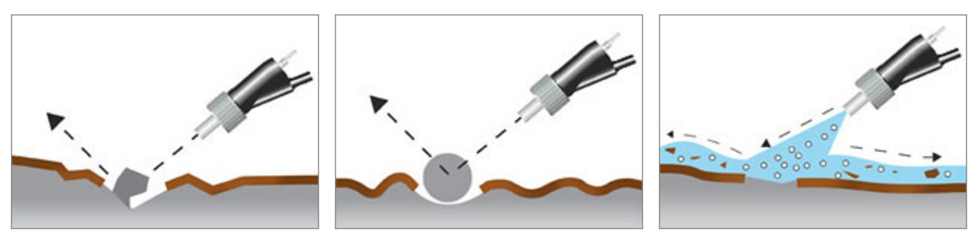

The aggressiveness of dry grit and bead blasting are shown in the first two illustrations which demonstrate the severe 8O ricochet that occurs when using these methods,

The third illustration shows the gentler, but just as effective, vapor blasting method. The ricochet of media is reduced due to the cushioning from the water: the angle of the media is changed producing a lapping effect traveling across the surface, giving an even satin/ polished finish.

The key to vapor blasting is that the finish is produced through flow of water borne abrasive, giving a finer finish due to the flushing action of the water. No media is impregnated into the component, nor is there any dust created by the break-up of media, unlike dry blasting where the finish is produced by sheer force of media impact.

A specially designed glandless polyurethane pump agitates water and media into a slurry, and pumps it to the blast gun. At the same time this slurry is pumped at approximately 2 bar to the nozzle, and air is introduced at the blast gun to accelerate the slurry and its cleaning effect on impact, albeit cushioned.

Typical Applications

Degreasing / surface finishing of components in the automotive, reconditioning & maintenance industries

Cleaning of dies & molds Removal of paint, rust, scale, carbon & similar deposits in engineering industries

Surface preparation prior to bonding, re-painting or re-coating

Satin finishing of stainless steels & other special materials

Cleaning of PCB's & electrical connectors

Removal of small burrs from manufactured components

Advantages of Vapor Blasting

Dust free process

Cleans by flow of water not by impact

Simultaneously degrease IS blast clean

Water acts as a lubricant between media & component Promotes longer media life Produces a 'softer' finish Avoids media impregnation on soft materials.

The illustrations below show the different natures of grit, bead, and vapor blasting.

© 2016 Augusta Powder Coat & Metal Restoration. All rights reserved.